To better understand how WellAir works, it is important to have the following concepts at hand:

Compressed Air

Compressed Air is air at a pressure higher than atmospheric. It is exactly the same air that you breathe, but reduced to a lower volume and maintained under pressure. Air is made up of 78% nitrogen, 20-21% oxygen, and 1-2% other gases and water vapor.

Condensation in compressed air

The newly compressed air is 100% saturated with water vapor which begins to precipitate as soon as the air cools in the after cooler, separator, air receiver, etc. This precipitant of water and other contaminants carried in the air ingested by the compressor, is known as condensate

Calculation of condensate flow

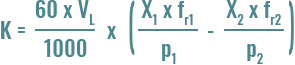

The volume of condensate that will be found is calculated by subtracting the admissible water from the water content in the air drawn in by the compressor and from the content in the pressurized working air. Resulting in the condensate flow rate in liters per hour.

Formula:

Where:

K: Condensate volume Liters / hour

Compressor VL: FAD m³ / min

frRelative Humidity

p: Pressure bar (a)

X: Water content at saturation in gr/m³

Main causes of condensation in compressed air lines

It is the transition of water from a gaseous state to a liquid state. when the water vapor pressure (PV) is greater than the saturation vapor pressure (PVS). This fact can occur because PV increases or because PVS decreases. The fundamental cause of a decrease in PVS is decreases in temperature.

In compressed air lines, additionally, the collision of particles at connections and angled turns condenses due to friction.

Parts of the compressed air system

Compression

Reducing the volume of air generates temperature so the newly compressed air reaches 180ºC

Dryer

It is a device based on coils and refrigerant that, by causing a thermal shock, precipitates condensation. Depending on the efficiency and size, the temperature can be lowered to an average of 38-45ºC.

Storage tank

The main objective of a compressed air tank is to act as temporary storage to adapt to system demand peaks and optimize the system's operating efficiency.

Line filter

In an industrial system with moderate or high air flow demand, the branches of the system are divided into heads and lines, each line is fitted with a filter and a condensate purge system or several depending on the length of the pipe.

Service filter

This device is placed at the point of application, either at the entrance of a piece of equipment, a tool or an applicator to collect moisture and particles before the final use of compressed air.

Application

Injection or extrusion of plastics, pneumatic tool, spray painting, Automated assembly, Fine coating finishes, surface ionization, Pneumatic pistons in process, Thermoformed by pressure valves, Etc.

The WellAIR uses the same principles to work

Colission

At the entrance and exit there are plate-shaped barriers placed where the air is impacted along its path so that the increased friction generates condensation.

Cyclone-Cooling

The WellAir chamber design causes the combination of pressure and centrifugal force to generate; at the same time, a vacuum chamber in the outer area of the cylinder.

So the following happens:

1.- The cyclone effect causes a decrease in temperature

2.- The centrifugal force throws the condensation and the particle outwards, entering the vacuum chamber and draining towards the WellAIR drainage area.

3.- When leaving, it collides again and the condensate generated is trapped in the cyclone effect following the same fate.

The result is dry, clean air at the point of application at that outlet temperature.